A key design feature shared by many 100-year-old barns and some modern skyscrapers is that the external shell carries the building's load with a minimal use of internal columns for support. Internal floors and walls, if any, function in a structural way to stiffen the building. This resourceful design allows for a very strong structure with a maximum of interior space available for other purposes.

The bones in the human body capitalized on this design feature long before farmers and architects did. In fact, studying bone construction and function provides a mini-course illustrating important engineering principles.

Sophisticated Engineering Properties

A quality product begins with materials that have superior engineering properties. Bone is constructed much like reinforced concrete, in which a cage of steel reinforcing bars ("rebar") is embedded. The reinforcing "rods" in bone are made from minute strands of collagen fibers, 360 of which could be put end-to-end in the width of a human hair.

Each fiber is composed of three substrands wound in rope-like fashion around each other so tightly that along the area of contact only the smallest amino acid would fit in the space between the strands. In order to work, this particular amino acid would need to be designated for every third position in each strand--which is exactly what is specified in the DNA code. Collagen fibers are linked so strongly that their resistance to being pulled apart in tension is actually greater than the resistance present in an equal amount of steel rebar.

The bone's equivalent of the cement/aggregate part of concrete is composed of apatite. Apatite is a medium-hard mineral with properties similar to marble and is found widely distributed in rocks. A microscopic view shows that individual apatite crystals are bound to the collagen fibers and linked as a continuous mesh--but at full size the structure appears solid. Compared to reinforced concrete, bone is more flexible and has more strength to resist crushing compressive loads. This is vitally important, since a man lifting a 70-pound box actually exerts a normal compressive load of over 500 pounds on one of his vertebrae--just imagine the loads of Olympic weightlifters.

An important area of engineering research is designing materials that are fatigue resistant. Fatigue is a progressive failure due to the localized and cumulative damage that occurs when material is subjected to cyclic loading. Counteracting this is imperative, since in one year each hip bone for the average person will sustain about 1.8 million cyclic loads. Bone is one of the most fatigue resistant materials known due to its unique blend of strength, stiffness, and flexibility.

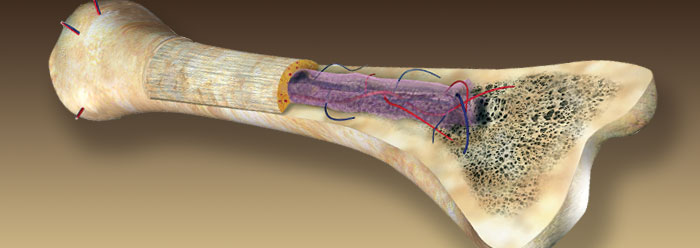

The actions of bending (compression/tension) and torsion (twisting) on bone are at their highest within the external shell. Dense-compact bone, able to resist these actions, is built into the shell. Inside, a three-dimensional network of small boney material resembling a porous sponge, called spongy bone, is found throughout small bones and at the ends of long bones. Spongy bone absorbs shocks and also contributes inner bracing or stiffness. The thin bony inner bracing elements do not grow randomly, but look and function like the support struts in the Eiffel Tower. Some studies demonstrate that if engineers apply a stress-strain analysis to a cross section of bone, it reveals that the boney braces are built along lines of maximum stress relative to the mechanical forces applied to them.

Fundamental Engineering Principles

Engineering efficiency strives for designs that completely fulfill an intended purpose while using minimal resources. Engineers can only dream of highways so efficient that they automatically expand from two to four lanes with population growth and contract with declines. In contrast, bone size does constantly change in response to demand throughout a person's life.

This highly efficient process called remodeling ensures that more bone is built in specific locations when it is subjected to heavy-repetitive loads and less is built when it carries lighter loads. In infants, 100 percent of the calcium is exchanged in their bones every year. For people in their 20s, the equivalent of 20 percent of the skeleton is replaced yearly--though high stress areas like inside the head of the upper leg bone may be replaced up to three times per year.

Remodeling also functions as a non-stop maintenance program for bone by tearing out old bone and replacing it with new. Concrete or block walls would last for ages if they had an outer covering that could continuously replace weak spots, repair cracks, or swap out rusty rebar. Remarkably, bones do possess such a covering.

The periosteum is composed of two important layers. The thin, lightweight outer layer consists of very flexible but extremely tough high-tensile-strength fibers akin to high-performance membranes that are now being utilized to wrap new buildings. The inner layer is composed mostly of two different types of cells kept in delicate balance--one type destroys bone and the other builds bone. These crucial cells are the workhorses for remodeling. The entire layer adheres tenaciously to the bone by means of strong, perforating fibers that embed in the collagen-apatite matrix. The concentration of these fibers varies and is appropriately very dense at spots where tendons connect to the bone.

A robust object withstands a lot of harm but continues functioning as intended. Sometimes the best response to a destructive force is to flex rather than to offer direct resistance. Automobile makers design "crumple zones" of materials intended to fold up or shear apart so crash forces are absorbed rather than transmitted to occupants.

Bones resist fractures in similar fashion. At the smallest level of collagen fibers, not all of the bonds are fixed solid. Some, called sacrificial bonds, are weaker bonds intended to break upon impact. Their exact arrangements in bone absorb and then disperse many forces that could rapidly reach the fracture threshold. But unlike a car's crumple zone, a bone's sacrificial bonds can repair themselves after the trauma, making them ready for another strike.

Damage Repair

Bones do have structural limits and can succumb to fractures that range from hairline to fully displaced. The cleanup and repair of bone exemplifies a thoughtfully engineered construction plan. A major fracture tears blood vessels, causing extensive bleeding and tissue swelling (pain results from torn or compressed nerves). Fortunately, blood eventually clots around the fracture, starting the healing. Within 48 hours, cells invade the blood clot and use it as a template to build a microfiber meshwork that acts as the "scaffolding" supporting the rest of the repair work. Other prerequisites to proper healing include broken bone ends being brought close together, aligned properly, and immobilized, with a sustained blood supply and the area kept free of infection.

The fracture zone is full of bone fragments and dead cells. Cells specialized in tissue demolition dismantle unusable bone fragments into their component parts. Other cells engulf and digest tissue debris. Valuable recyclable materials are saved and actual wastes carried off in the bloodstream to be discarded.

Man-made splints support fractures to prevent large damaging movements, but the broken ends still need further stabilization. Certain cells, called fibroblasts, work off of the "scaffold," laying down collagen fibers to span the break. Once some of the collagen bridge is made, new cartilage can be placed concurrently around the fibers. Fibroblasts will transform themselves into chondroblasts to produce this cartilage. Once built, the collagen-cartilage unit functions as new inner rebar, forming material (controlling the shape and location of the new bone), and the temporary bracing--all in one package.

Bones are living tissue and need to be nourished. Inside bone is an ingenious system of microscopic canals that comprise a thoroughfare to shuttle nutrients. Bone-building cells have multiple slender arms that radiate out from the cell body. When new bone is made, hundreds of these cells join their arms together to form a three-dimensional network that will become the basis of the canal system.

These cells will actually build new bone all around themselves and thus become entrapped within the bone. In essence, the cells not only make boney "concrete," but amazingly become their own forming material for the interior canals. With its job making bone now complete, this cell transforms itself into a nourishing/pressure-sensor cell called an osteocyte. Repair and remodeling processes make bone so resilient that in time a repaired bone may look almost identical to the original.

Conclusion

Bone structure is an engineering marvel. For its stress environment, it achieves nearly maximum mechanical efficiency with minimum mass, which designers call an optimized structure. Thus, bones remain a testimony to the genius of their Creator, the Lord Jesus Christ. In fact, bones are such an important feature in human design that they will remain with us for all eternity in our resurrected bodies, as Jesus demonstrated for His disciples (Luke 24:39).

Image Credit: ©Getty Images/Dorling Kindersley

*Dr. Guliuzza is ICR's National Representative.

Cite this article: Guliuzza, R. 2009. Made in His Image: Bone, An Engineering Marvel. Acts & Facts. 38 (7): 10.